In today’s fast-evolving manufacturing sector, data is a critical asset. Among various forms of data, Master Data plays an indispensable role. From product specifications and suppliers to customer information and operational processes, Master Data is at the core of every manufacturing organization’s operations. In this blog, we’ll explore what Master Data is, why it matters to manufacturing industries, and how leveraging it can lead to improved efficiency, reduced costs, and streamlined operations.

What is Master Data?

Master Data refers to the critical business information shared across an organization. It typically includes key data about:

- Products: Specifications, designs, materials, and more.

- Customers: Profiles, preferences, purchase history, etc.

- Suppliers: Vendor details, contracts, terms of service.

- Assets: Machines, tools, maintenance schedules.

Master Data acts as the foundation upon which companies build their day-to-day activities and strategic planning. It differs from transactional data, which records day-to-day operations, such as sales orders or shipping records. Master Data provides a single version of truth, ensuring consistency and accuracy across various systems and processes within a company.

Importance of Master Data in Manufacturing

- Consistency and Accuracy in Operations In manufacturing, consistency is crucial. From managing inventory to producing goods, accurate Master Data ensures that all departments are working with the same, up-to-date information. Errors in production often stem from poor data quality, which can lead to incorrect material orders, production delays, and even faulty products. Proper Master Data Management (MDM) eliminates these inefficiencies.

- Optimized Supply Chain Management Manufacturers rely on numerous suppliers to maintain operations. Effective MDM helps streamline the supply chain by ensuring that supplier information is accurate and up-to-date. With a well-maintained Master Data system, manufacturers can avoid delays, overstocking, and stockouts, ensuring seamless supply chain management.

- Improved Regulatory Compliance Manufacturing industries are heavily regulated, with specific requirements for product specifications, safety standards, and environmental regulations. Accurate Master Data is critical for maintaining compliance. For instance, maintaining up-to-date records of raw materials or certifications is essential for adhering to industry regulations.

- Enhanced Decision Making Master Data supports advanced analytics, which in turn drives better decision-making. With reliable data on customers, products, and suppliers, manufacturing companies can make informed strategic decisions. Whether it’s pricing, product development, or market expansion, decisions backed by high-quality data are more likely to succeed.

- Facilitating Industry 4.0 Transformation The manufacturing industry is embracing digital transformation and Industry 4.0 technologies such as IoT, AI, and robotics. These technologies rely on clean and organized data. Master Data serves as a foundation for these advanced systems, helping manufacturers leverage predictive analytics, automation, and real-time monitoring.

Challenges of Managing Master Data in Manufacturing

- Data Silos: Often, departments maintain their own versions of data, leading to inconsistencies.

- Data Duplication: Duplicate records across systems cause inefficiencies and data conflicts.

- Complex Supply Chains: With global suppliers, managing data about various entities becomes cumbersome.

Addressing these challenges requires a robust MDM system that can standardize, clean, and manage data across the entire organization.

Benefits of Implementing a Robust MDM System

- Streamlined Operations: With accurate and consistent data, manufacturers can ensure smooth, uninterrupted operations.

- Reduced Costs: By eliminating redundancies and inefficiencies, MDM can significantly reduce operational costs.

- Better Customer Experience: Reliable data allows manufacturers to offer more personalized and timely services to their customers.

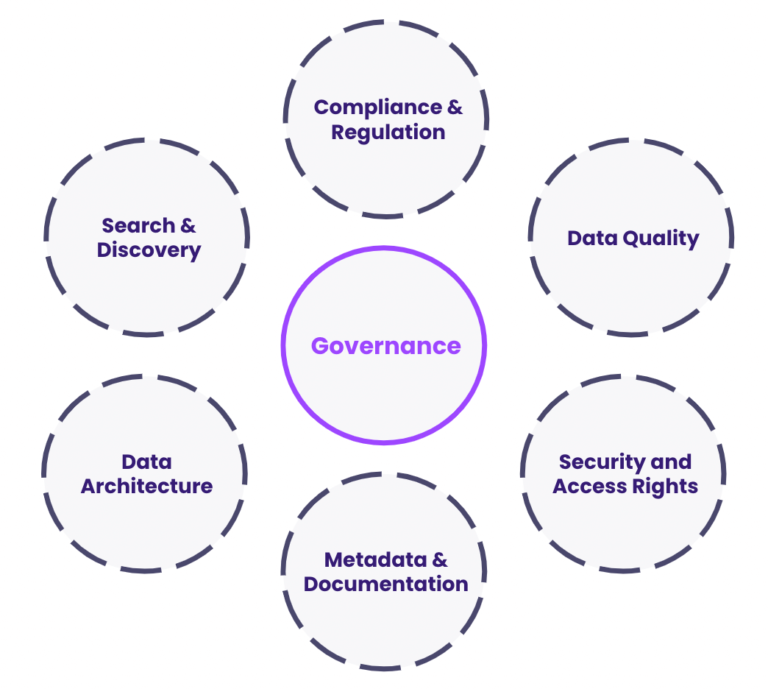

- Data Governance and Security: A good MDM system ensures that sensitive data is managed securely and complies with all relevant regulations.

Conclusion

For manufacturing industries to remain competitive in an increasingly digital world, managing Master Data effectively is non-negotiable. It ensures operational efficiency, better decision-making, compliance, and a smoother transition to Industry 4.0. By investing in a robust MDM solution, manufacturers can harness the full potential of their data, leading to improved productivity and profitability.